- Steel Structure

- Steel Structure Warehouse

- Steel Structure Workshop

- Steel Structure Building

- Prefabricated House

- Container House

- Poultry House

- Sandwich Panel

- Steel Structure Chicken House

- Steel Structure Material

- Poultry House

- Sandwich Panel

- Shipping Container House

- Modular Container House

- Prefabricated Home

- Steel Structure Poultry House

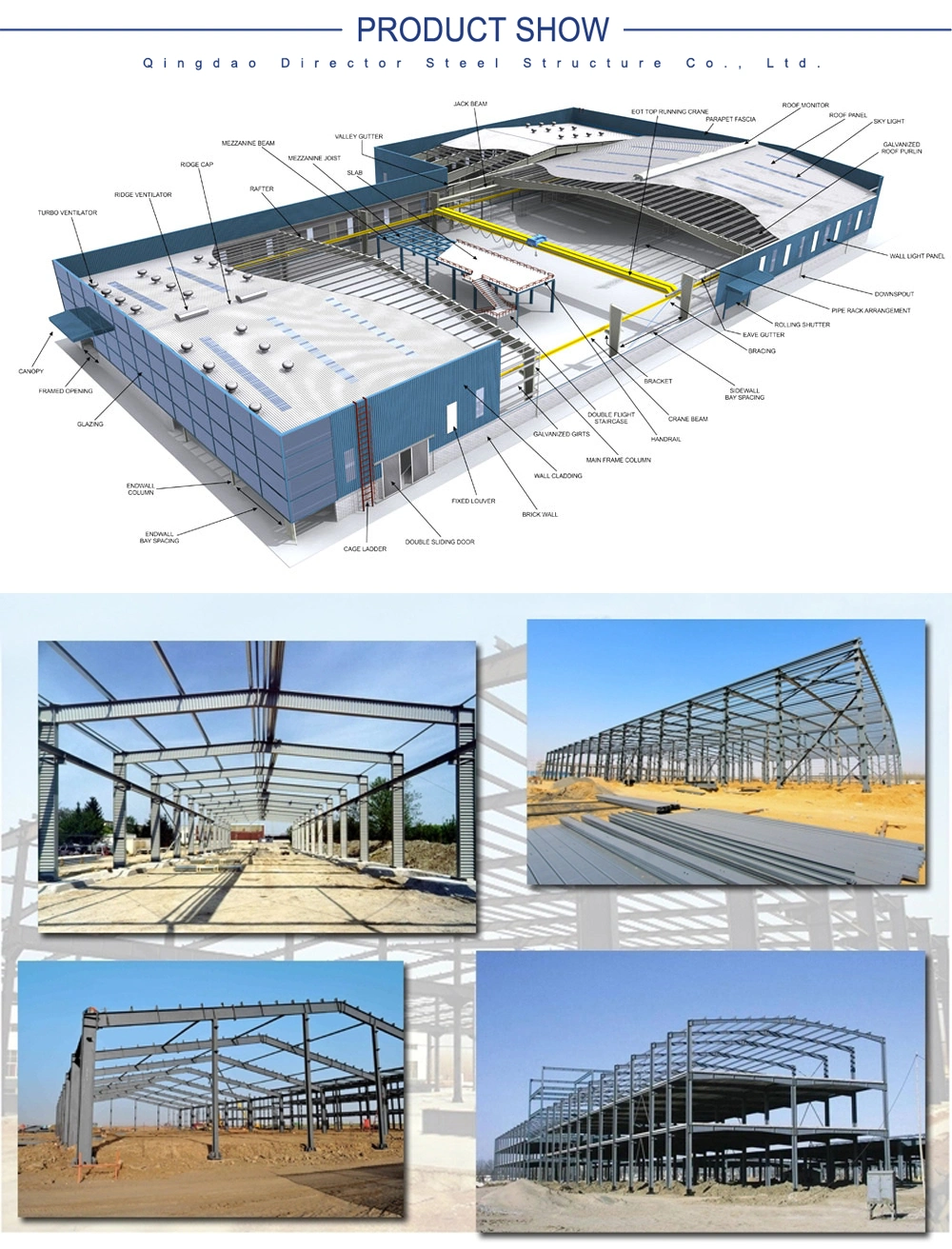

Prefabricated Construction Building Material Poultry Farms Chicken House Hangar Steel Structure Warehouse Workshop

Basic Info

| Type of Steel For Building Structure | H-Section Steel |

| Carbon Structural Steel | Q235 |

| Residential Wall Structure | Wall Stud |

| Application | Steel Workshop, Steel Structure Platform, Steel Fabricated House, Structural Roofing, Frame Part, Steel Walkway and Floor, Steel Structure Bridge |

| Insulation | PU/PIR/EPS/Rock Wool/Fiberglass Wool, etc. |

| Windows | PVC/Plastic Steel/Aluminum Alloy Window |

| Wind Resistance | Grade 14 |

| Door | Sandwich Panel Sliding Door or Rolling Door |

| Column&Beam | Hot Rolled/Welded H-Section Steel |

| Roof and Wall Cladding | Sandwich Panel or Colored Corrugated Plate |

| Lifespan | More Than 50 Years |

| Surface Processing | Surface Processing |

| Steel Grade | Q235B, Q345b |

| Drawing | Customized Design |

| Purlin | C/Z Shape Galvanized Steel |

| Installation | on-Site Installation Service |

| Foundation | Concrete Foundation/Anchor Bolt |

| Earthquake Resistance | Grade 8 |

| Transport Package | Flat Packed in Container or as Request |

| Specification | Customized |

| Origin | China |

| HS Code | 9406900090 |

| Production Capacity | 50000 Tonss Per Month |

Product Description

Low Cost Factory Warehouse Workshop Light Prefabricated Steel Structure Building

Director Group prefabricated steel structure building has features of high fire resistance, strong corrosion resistance. Steel structure warehouse is mainly refers to the main bearing component is composed of steel. Including the steel columns, steel beam, steel structure, steel roof truss.Each component using welds, bolts or rivets to connect.

The roof and wall can be made of composite panel or veneer. Galvanized sheet metal can prevent rust and corrosion. The use of self-tapping screw can make the connection between the plates more closely, to prevent leakage. You can also use composite panel for roof and wall. The sandwich is polystyrene, glass fiber, rock wool, polyurethane. They have good thermal insulation, heat insulation, fire-retardant. The wall of the steel structure maintenance also can use brick wall. The cost of a brick wall is higher than galvanized steel roof and wall.

The usage scale includes large-scale workshop, or warehouse, supermarkets, entertainment centers and modular steel structure garage.

1. Specification

| Items | Specification | |

| Main Steel Frame | Column | Q235, Q345 Welded H Section Steel |

| Beam | Q235, Q345 Welded H Section Steel | |

| Secondary Frame | Purlin | Q235 C and Z purlin |

| Knee brace | Q235 Angle Steel | |

| Tie Rod | Q235 Circular Steel Pipe | |

| Brace | Q235 Round Bar | |

| Vertical and Horizontal Support | Q235 Angle Steel, Round Bar or Steel Pipe | |

| Maintenance system | Roof Panel | EPS Sandwich Panel / Glass Fiber Sandwich Panel / Rock Wool Sandwich Panel / Pu Sandwich Panel /Steel Sheet |

| Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

| Accessories | Window | Aluminiumn Alloy Window / PVC Window / Sandwich Panel Window |

| Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door | |

| Rainspout | PVC | |

| Live load on Roof | In 120kg/Sqm (Color steel panel surrounded) | |

| Wind Resistance Grade | 12 Grades | |

| Earthquake-resistance | 8 Grades | |

| Structure Usage | Up to 50 years | |

| Finishing Options | Vast array of colors and textures available | |

| Paint Options | Alkyd paiting, two primary painting, two finish painting (gray paint, red paint, white paint, epoxy zinc etc.) Or Galvanized. | |

2. Advantages

(1). Free to design architectural drawings for you;(2). Features: Fast and flexible to assemble, safe, thermal and noise insulation, water proof and fire prevention;(3). Cost-effective: Fast and easy installation greatly shorten the construction time which reduce the costs;(4). Durability: The whole structure is easy in maintenance, which can be used for more than 50 years.(5). Perfect design: Perfect design completely avoids leaks and water seepage. Meanwhile, it's also in line with the national level of fire prevention.(6). Carrying capacity: can resists the impact of strong wind and seismic performance and bears heavy snow loads

Some main oversea projects we undertook in the past couple months:

1. Tanzanina 450 square meter steel structure workshop2. New Zealand 207 square meter prefab office3. French Polynethia 450 square meter steel structure warehouse4. Ghana 162 square meter powder mining building5. Maldives 48X30X12M hangar repair building6. Australia 440 square meter pig feeding building7. Russia 320 square meter steel structure workshop in two storey8. Belarus 1150 square meter steel structure warehouse9. Philippines chicken house10. Philippines chicken house11. Ghana 100*12*5m 2 sets chicken house12. Peru 7*15*20 four strory workshop building13. Peru 21.5*15*12 workshop building14. Peru 25*20*24 four strory workshop building15. Mozambique simple villa house16. NIGERIA 1200 SQM steel structure workshop17. SAMOA 400 sqm steel structure church building18. SAMOA 900 sqm steel structure warehouse19. SAMOA connect plates, Z purlin, two strorey house structure20. NIGERA 4 SETS 54*13*2.5M chicken house21. AUSTRALIA 32*18*6.5m warehouse22. SAMOA Z purlin, connection plate23. Algeria 54m*13m*2.5m 4sets chicken house24. AUSTRALIA 5 sets of 11*20*4.2m farm shed25. AUSTRALIA 41.8*18.6*7.7m two storey office building26. SAMOA 24x12x4.5m warehouse 2sets27. SAMOA 14.4*12*3.6 living house28. SAMOA 71.2m*58m*12m two story supermarket building29. Algeria 54x30x6m workshop building30. Cookes 75x12x2.5m chicken house31. Australia LED sign structure (2 sets)32. Algeria 100x37x9m granite processing workshop33. Samoa 44.7x33x8.5m supermarket building34. Saint Lucia 36*15*3 warehouse35. Saint Lucia office building36. Qatar car shed37. Angola 20*18*6.5m workshop and office38. USA 24*12*4.8M warehouse39. Australia prefab house40. Papua New Guinea 4 strory workshop building41. Mauritius 800 SQM steel structure workshop42. Uruguay 600 SQM steel structure workshop43. Georgia 2000 SQM automobile repair house44. Venezuela 150x15x1.9m chicken shed (12 sets)45. Panama 2000 sqm Pharmaceutical factory46. Georgia 1000 sqm steel workshop47. CAMEROU 1200 sqm church house (3 sets)48. Ghana 1000 sqm office house (3 sets)49. India 12500 sqm factory building

FAQ

A: We are manufacture factory. And you are welcomed to visit us for inspection. The quality control flow will show you ourprofessional. Also you will enjoy the best quality and competitive price.

Q: Whats the quality assurance you provided and how do you control quality ?

A: Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. SGS, BV and other testing are available for us.

Q: Can you offer designing service?

A: Yes, we have more than 10 design engineers. We could design full solution drawings as per your requirments. They use software: Auto CAD,PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)V12.0.etc.

Q: Do you offer guiding installation on site overseas?

A: Yes, usually we will send you the detailed installation drawing, if you need, we can provide the service of installation, supervision and training by extra. We can send our professional technical engineer to supervise installation on site overseas.

Need Quotation?

Our excellent design team will design the steel structure workshop warehouse for you. If you give the following information, we will give you an satisfactory drawing.1 Location (where will be built? ) _____country, area2 Size: Length*width*height _____mm*_____mm*_____mm3 wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s4 snow load (max. Snow height) _____kn/m2, _____mm5 anti-earthquake _____level6 brickwall needed or not If yes, 1.2m high or 1.5m high7 thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.8 door quantity & size _____units, _____(width)mm*_____(height)mm9 window quanity & size _____units, _____(width)mm*_____(height)mm10 crane needed or not If yes, _____units, max. Lifting weight____tons; Max. Lifting height _____m